What is FUNCSTER™?

FUNCSTER™ is a high-performance long glass fiber reinforced thermoplastic resin developed by our original technology.

Product Description

FUNCSTER™ is manufactured by leading glass fiber rovings(Fiber bundle) consisting of several thousand filaments through an impregnation die, impregnating the filaments uniformly with molten thermoplastic resin, cutting them to the required length (usually 5 to 15 mm), and pelletizing them.

In the case of conventional short-fiber reinforced resins, chopped strands of glass fiberand thermoplastic resin are melt-kneaded in an extruder, so the glass fibers are pulverized to about 0.5 mm, but with FUNCSTER™, the glass fiber length is the same as the pellet length. Thus, for example, if the pellet length is 10 mm, a reinforced resin with a fiber length 20 times that of short-fiber reinforced resin is obtained.

FUNCSTER™ Features

In FUNCSTER™ moldings, glass fibers exist in a long state of entanglement.

This gives FUNCSTER™ the following features

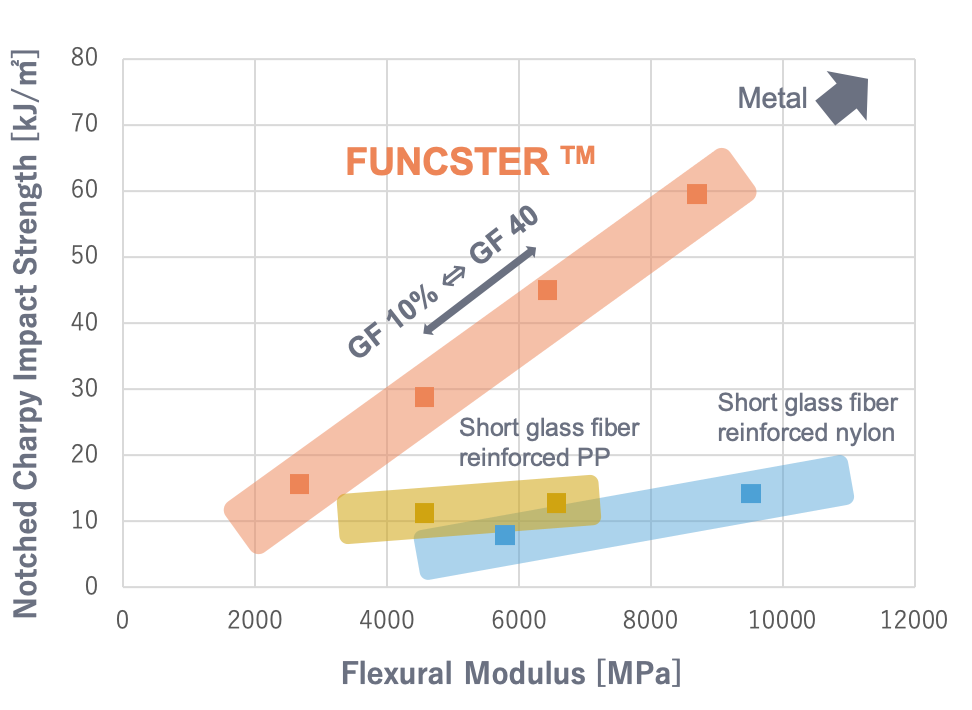

- Energy is absorbed and impact resistance is dramatically improved.

- Excellent rigidity.

- The long residual fibers have a greater reinforcing effect, resulting in superior mechanical strength, such as tensile and bending strength.

- The product has excellent It also has excellent durability such as creep and vibration fatigue characteristics.

Excellent high-temperature properties such as temperature dependence of stiffness, heating deformation, and linear expansion coefficient. - Low shrinkage and low anisotropy, resulting in molded products with less warpage and twitching compared to short-fiber reinforced resins.

- Molded products with thick walls and ribbed moldings have fewer sink marks.

- In molded products with normal wall thickness, glass fibers do not show up on the surface and the appearance is good.

- Melt flowability is extremely good and moldability is excellent.

Steaming sample

FUNCSTER™ molding steamed at 600°C

JIS heat deformation temperature test piece 6.4×12.7×127mm

Reduction of CO2 emissions from automobiles, extension of cruising range due to conversion to EV vehicles, etc.

We develop and propose “lightweight and highly rigid materials" that can contribute to environmental friendliness.

<Features>

In addition to high strength, it has “good flow” and “high appearance”.

We aim to reduce environmental impact by eliminating painting (no painting).

*Specific strength is about 3 times that of steel, and 20-40% weight reduction of parts is possible.

Application examples

This is examples of product applications that takes advantage of the characteristics of FUNCSTER™.

Large-Sized Automotive Components

Metal Substitution for Automotive Components

Metal Substitution for Automotive Components

Grade list/Download

Physical properties of FUNCSTER™

- This is a typical data, not to be construed as specification.

- Application suitability should be confirmed with the final product by referring to the physical property values.