Core Technologies Metallocene Catalysts

What is a metallocene catalyst?

Metallocene catalysts are single-site catalysts with homogeneous active sites discovered by Professor Kaminsky and his colleagues at the University of Hamburg, Germany, in 1980. The polymers obtained from these catalysts have many excellent features that cannot be obtained with conventional catalysts, such as narrow distribution of molecular weight and comonomer content. In the case of ethylene-based polymers, various performance improvements have been achieved, leading to the commercialization of new elastomers and plastomers.

In polypropylene, on the other hand, the balance between cost and polymer performance (molecular weight and regularity) could not be achieved beyond the conventional catalyst technology, making practical application far more difficult. We solved these problems by making full use of our original complexation design technology and catalyst/support technology, and launched the world's first metallocene catalyst-based random copolymer "WINTECTM " in 2001.

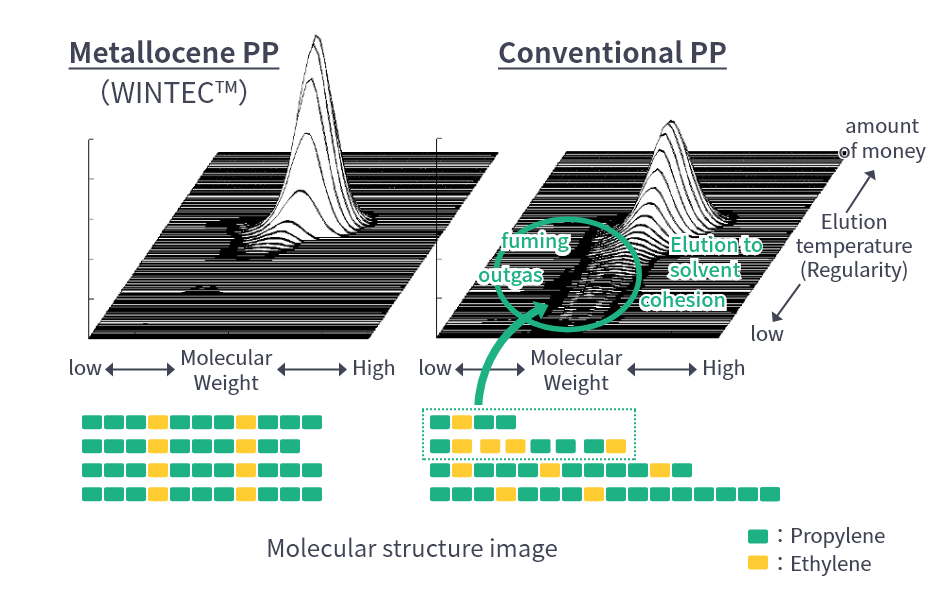

WINTECTM is widely used in films, medical devices, IT-related products, cosmetic containers, etc., by taking advantage of its features such as low regularity, low molecular weight components, and uniform composition (Figures 1 and 2) to achieve low melting point, low contamination and elution, and high transparency, which were difficult to produce with conventional (Ziegler-Natta) catalysts. We are expanding our business widely to films, medical devices, IT-related products, cosmetics containers, etc.

Figure 1: Characteristics of metallocene PP [Narrow molecular weight and composition distribution]

*Low molecular weight and low regularity components that lead to various harmful effects are reduced.

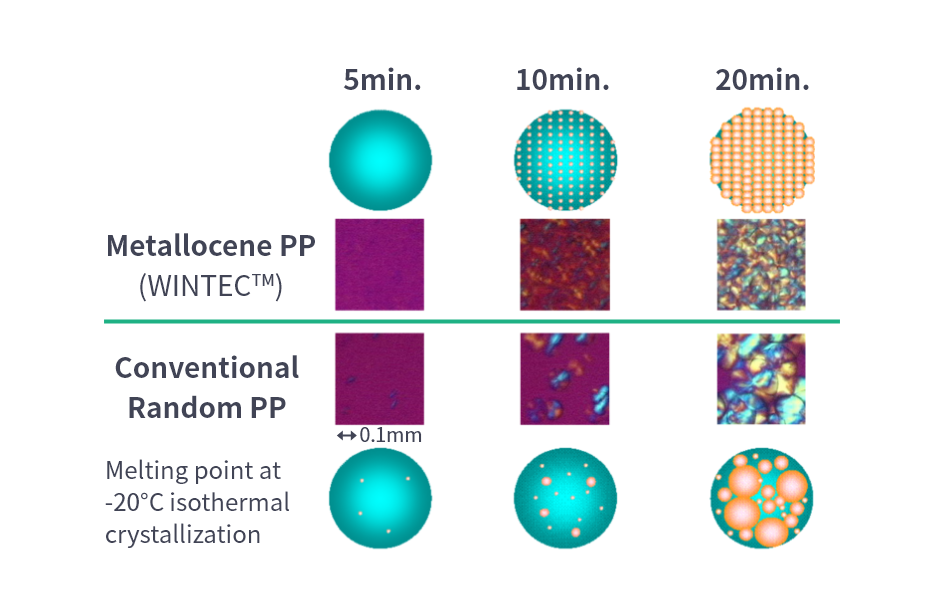

Figure 2: Characteristics of metallocene PP [Uniform crystallization behavior]

High transparency due to uniform and fine crystal structure

We have further developed the application of metallocene catalysts and achieved the commercialization of WAYMAX™ , the world's first polymerized, long-chain branched polypropylene, using a new catalyst that utilizes unique high copolymerization properties and molecular structure control technology.

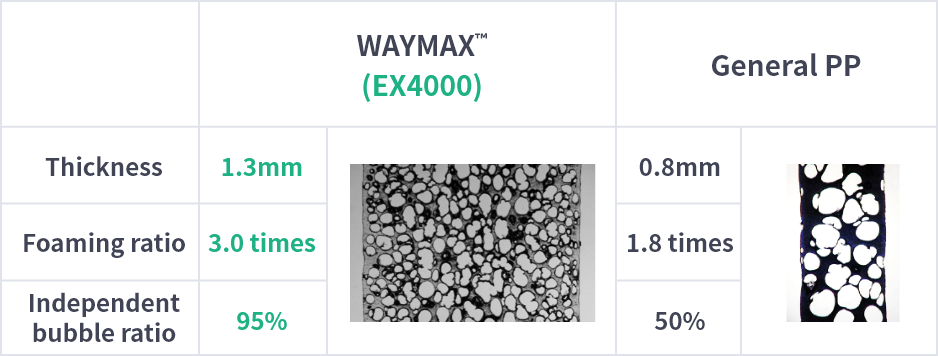

WAYMAX™ exhibits excellent moldability by taking advantage of its high melt strength and strain hardening properties derived from its long-chain branch. In foam molding, high foaming ratio and uniform and fine bubble formation are possible (Fig. 3, Fig. 4). In thermoforming and blow molding, it is highly effective in controlling drawdown and uniformity of wall thickness, as well as in uniform spreading in laminate molding processes. Furthermore, compared to cross-linked branched PP, it is more thermally stable and has excellent recycling characteristics, making it a material that can make a significant contribution to reducing environmental burdens.

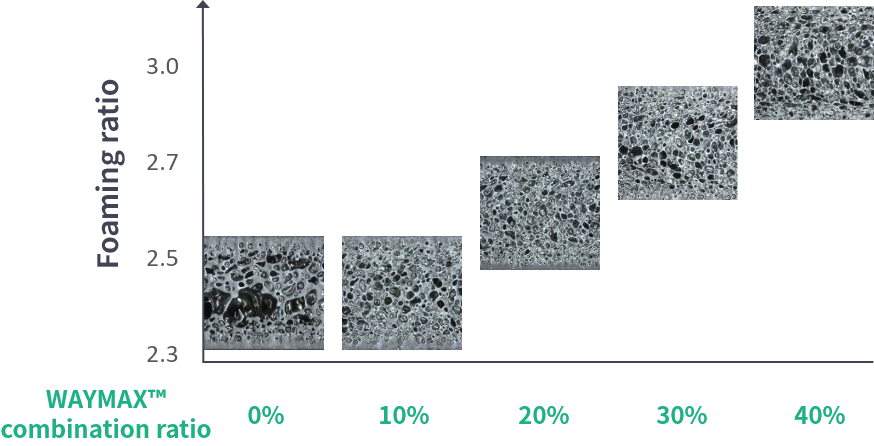

Figure 3: T-die and extrusion foaming characteristics of WAYMAX™

Excellent ductility and bubble retention, high foaming ratio and independent bubble ratio

Figure 4: Core-back and injection foaming characteristics(general PP modification)

Even when added in small amounts, it greatly improves foaming characteristics, achieving both high quality and high magnification.